SNT Energy

Selective Catalyic Reduction System

The Leader of Generator / Petrochemistry Plant

S.C.R System

- Home

- Business

- S.C.R System

NOx, SOx, Dust Cleaning Technology

- Air polluting materials such as NOx, dioxin, SOx, dust and VOC, exhausted from boilers and vehicles that burn fossil fuels and convert them into energy, are exposed to the air, and give seriously harm effects to the ecosystem of the mankind, animals and plants.

- The denitrification facility eliminates the NOx materials, generated from combustion of nitrogen component in fuels and air. Because improvement of the combustion conditions has a technical limitation in the reduction efficiency and it requires additional treatment facilities after combustion, the most reliable selective catalytic reduction (SCR) system occupies most of the NOx materials elimination markets.

- The desulfurization facility eliminates the SOx materials, generated by reaction between the sulfate components and the oxygen in process of combustion of fuels. It is obligatory to install desulfurization facilities for large-scaled power plants and incineration facilities in Korea and other overseas countries. Installation of desulfurization facilities for the medium-sized boilers has not been active, but the facilities have an infinite marketing potential in the future owing to localization of the relevant technology and the economical prices.

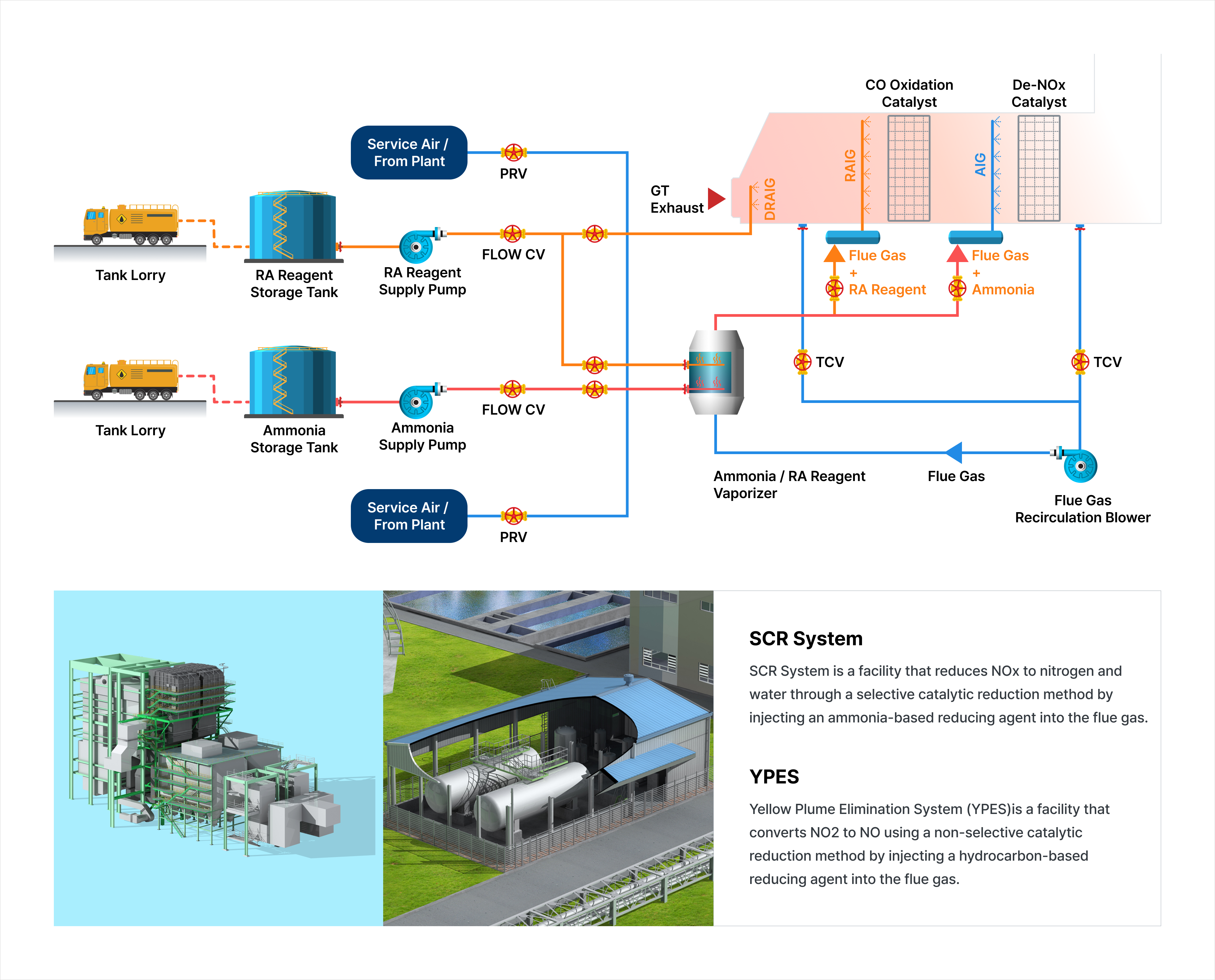

A systematic map of S.C.R System

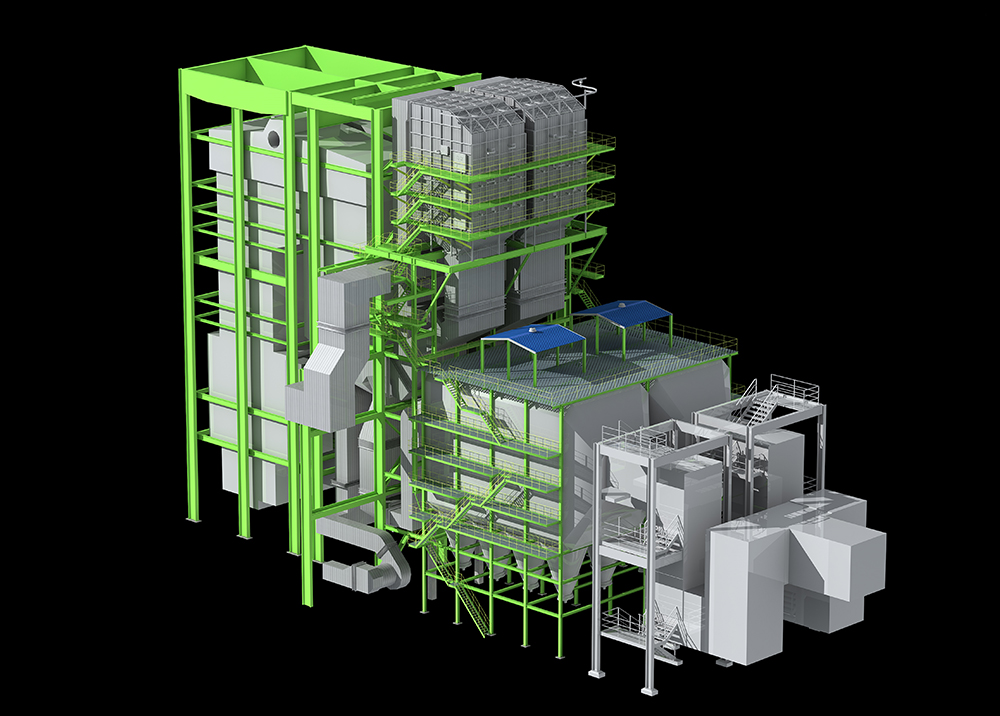

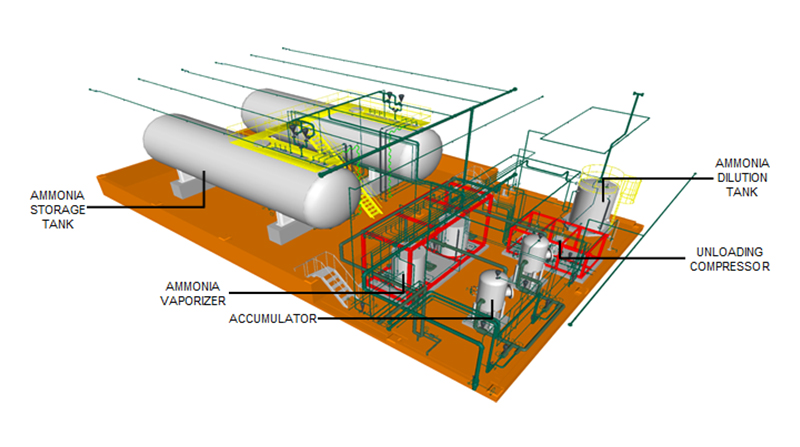

Design : Honam Thermoelectric DeNox and Ammonia Building Air View

-

- Honam Thermoelectric two 250MW

- Honam Thermoelectric Ammonia Facility for DeNox Facility

-

Features

-

SCR System

-

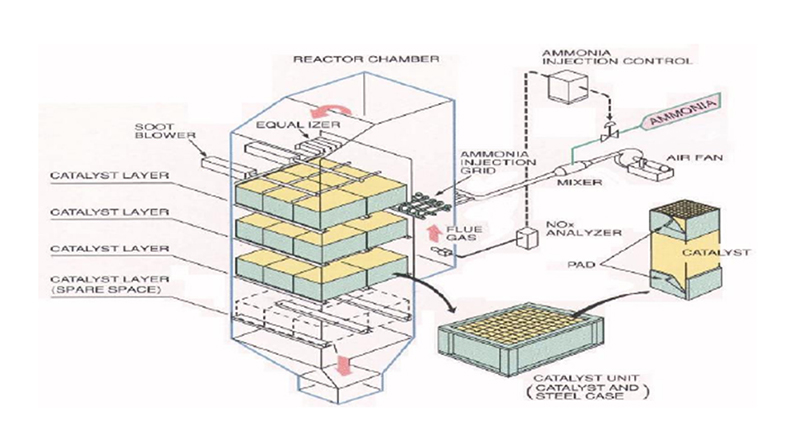

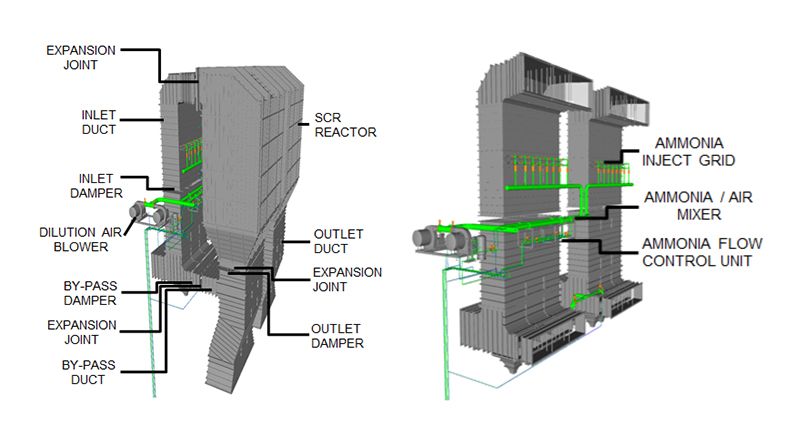

SCR Reactor and Duct

- Own Technology and Design Ability for Process and System

- High De-NOx Efficiency

- Low Ammonia Slip

- Low Conversion Rate of SO2 to SO3

- Low Pressure Drop

- Design for Even Distribution of Flue Gas

- Easy Loading and Replace of Catalyst

- Optimum Design

- Duct and Reactor Reinforced to Minimize Deflection

- Design Guide Vane to Well Distribution of Flue Gas and Low Pressure Drop at Duct and Reactor

Ammonia Facility Design Features

-

Ammonia Storage and Handling System

- Efficient Arrangement of Facilities

- Abundant Experience of Ammonia Storage and Handling System

- Design and Manufacturing Ability

- Design Ability All Kinds of Reagent Storage and Handling System

- Design and Manufacturing under Control of Very Specialist in Field of High Pressure Gas

- Design for Safe Operation and Easy Maintenance

- All Safety Equipment for Safe Operation

- Skid Design for Easy Installation

- 3D Modeling Design to Avoid Interference

Experience List

| Plant | Capacity (MW) | Year | Client | Installation | Fuel |

|---|---|---|---|---|---|

| Taean TPP Unit 8 (Performance Improvement) |

500 | 2023 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 7 (Performance Improvement) |

500 | 2023 | Korea Western Power | High Dust | Coal |

| Daegu CHP | 280 | 2023 | Korea District Heating Corp. | HRSG | LNG |

| Cheongju CHP | 280 | 2023 | Korea District Heating Corp. | HRSG | LNG |

| Datan CCPP Unit 6 | 750 | 2020 | Taiwan Power Company | HRSG | LNG |

| Datan CCPP Unit 5 | 750 | 2020 | Taiwan Power Company | HRSG | LNG |

| Nam Jeju CCPP | 160 | 2019 | Korea Southern Power | HRSG | LNG / Light Oil |

| Young Nam CCPP | 400 | 2017 | KOSPO Young Nam Power | HRSG | LNG |

| Thai Binh2 TPP Unit 2 | 600 | 2016 | Vietnam Oil & Gas Group(PVN) | High Dust | Coal |

| Thai Binh2 TPP Unit 1 | 600 | 2016 | Vietnam Oil & Gas Group(PVN) | High Dust | Coal |

| Taean TPP Unit 10 | 1,050 | 2016 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 9 | 1,050 | 2016 | Korea Western Power | High Dust | Coal |

| Honam TPP Unit 1 | 250 | 2009 | Korea East-West Power | High Dust | Coal |

| Honam TPP Unit 2 | 250 | 2009 | Korea East-West Power | High Dust | Coal |

| Taean TPP Unit 5 | 500 | 2007 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 4 | 500 | 2007 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 1 | 500 | 2006 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 2 | 500 | 2006 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 3 | 500 | 2006 | Korea Western Power | High Dust | Coal |

| Taean TPP Unit 6 | 500 | 2006 | Korea Western Power | High Dust | Coal |

| Inchon TPP Unit 1 | 250 | 2002 | Korea Midland Power | High Dust | Coal |

| Inchon TPP Unit 2 | 250 | 2002 | Korea Midland Power | High Dust | LNG / LSWR |

| Nowon Co-Gen Power | 37 | 2002 | SH Corporation | Low Dust | LNG |

| Mokdong Co-Gen Power | 20 | 2002 | SH Corporation | Low Dust | LNG |